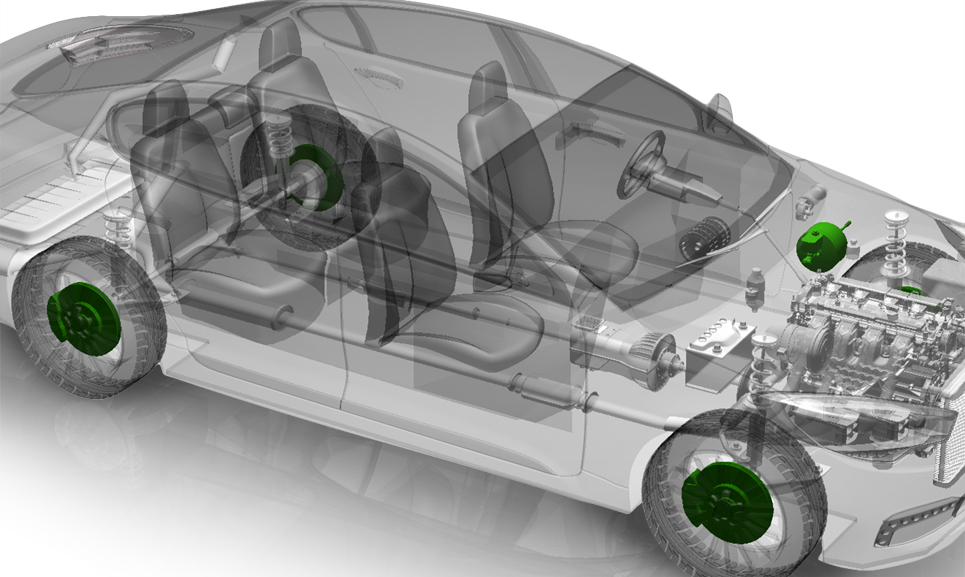

Braking System

Material Analysis

- Determination of the chemical composition of metallic materials (spectral analysis, CS combustion)

Analysis of brake fluids

- Physical and chemical key data

- Analysis of components

- Residue analysis

Dynamic Tests in Front, Side and Rear impact

- We carry out tests on interior and exterior components using two modern systems, an impact sled and acceleration sled.

Tensile tests according to specifications (EG, ECE, FMVSS, ADR)

Corrosion Protection and Expertise

UV Weathering

Temperature-Climate Change Tests

Salt Spray Test

- Determining the corrosion resistance of a material or an anti-corrosive coating

Mechanical and Technological Testing

- For static and dynamic material stresses on standardised specimens and complex machine components

- Mechanical specimen processing

Simulation of Technical Heat Treatment

- In inert gas atmosphere

Light Macroscopic Tests

- Creation of sections and structure tests / assessments of all materials and material combinations

- Section preparation and etching / specific etching

- Qualitative and quantitative section evaluation (incident / transmitted light microscope)

- Photographic documentation using digital image processing

Scanning Electron Microscopy

- Cause of fracture and determining of the fracture mechanism

- Energy dispersive X-ray microanalysis (EDX) inc. element distribution models (mapping)

Macroscopic Tests

- Visual / stereo microscopical assessments of cases of damage and estimation of the additional time and effort for the test

Material Tests

Development Support/ Homologation Testing

Field Test, Damage Analysis

Quality Assurance Tests / Conformity of Production

Emergency-brake assist

Always in operation, detects critical situations, warns the driver at an early stage, provides time to react