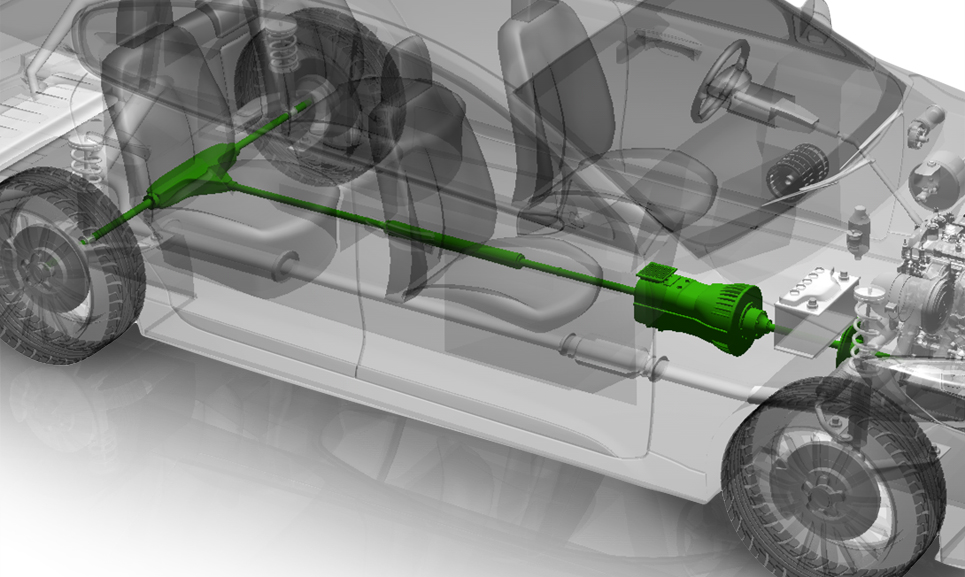

Gear Box and Motor

Material Analysis

- Determination of the chemical composition of metallic materials (spectral analysis, CS combustion)

Corrosion Protection and Expertise

Voltage Measurement using Strain Gauges- (DMS) Technique

- Measuring equipment for recording stretching deformations

- Change their electrical resistance even in the case of limited deformations and are used as strain sensors

Exhaust emission testing of petrol and diesel engines

Exhaust emission testing of vehicles that run on Natural Gas, LPG or Hydrogen

Durability and Aging Analyses of engines

Durability and Aging Analyses of complete power trains

Ultrasound, Magnetic Particle Crack and Dye Penetration Testing

- Suitable test procedure for detection of internal and external faults in sound-conducting materials (these include most metals) (ultrasound testing)

- Procedure for the detection of fractures on or near the surface of ferromagnetic materials (magnetic particle crack testing)

- The capillary forces of fine surface cracks and pores are used to make these visible (dye penetration testing)

Testing of Natural Gas and LPG Systems

Salt Spray Test

- Determining the corrosion resistance of a material or an anti-corrosive coating

Mechanical and Technological Testing

- For static and dynamic material stresses on standardised specimens and complex machine components

- Mechanical specimen processing

Quality Assurance Tests / Conformity of Production

Field Test, Damage Analysis

Development Support/ Homologation Testing

Material Tests

Macroscopic Tests

- Visual / stereo microscopical assessments of cases of damage and estimation of the additional time and effort for the test

Scanning Electron Microscopy

- Cause of fracture and determining of the fracture mechanism

- Energy dispersive X-ray microanalysis (EDX) inc. element distribution models (mapping)

Light Macroscopic Tests

- Creation of sections and structure tests / assessments of all materials and material combinations

- Section preparation and etching / specific etching

- Qualitative and quantitative section evaluation (incident / transmitted light microscope)

- Photographic documentation using digital image processing

Simulation of Technical Heat Treatment

- In inert gas atmosphere

Technical cleanliness

- Residual dirt VDA 19 / ISO 16232

- Air extraction of air-ducting components